Adsorption Column Design Procedure

Are the analytical equations still valid. Treated through a column packed with the adsorbent allow-.

Packed Bed Column Adsorption Of Phenol Onto Corn Cob Activated Carbon Linear And Nonlinear Kinetics Modeling Sciencedirect

The amount of carbon dioxide that is removed from the unit per day is 2352kg.

. Absorption Stripping Design Common assumptions. This article Part 2 covers the most widely used adsorbents in order of decreasing commercial importance 2 3. Modeling of Adsorption Processes.

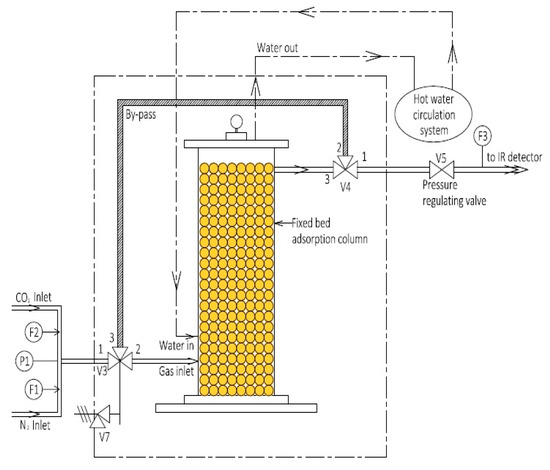

The two gas streams mix at a tubing cross where the pressure transducer is also attached. The situation is more complex than that for a simple stirred-tank batch process which reaches equilibrium. Adsorbents work by contact time.

Ive designed the adsorption column. Adsorbent then after separation of. Solvent or carrier is cleaned before.

Put an adiabatic flash first. X x L t uAt AL qt V VAL cc t c x D D p p iis D i D φ φ 0 x. Mass-transfer resistances are important.

Fundamentals of adsorption system design. STEPS USED DURING DESIGN OF ABSORPTION COLUMN Selection of solvent Selection of column type Selection of packing Equilibrium data Material balance Minimum solvent flow rate 4. If the feed is not two phase at the desired pressure use an isothermal flash.

Continuously fed into column 2. As for my 3rd Year Design Project I was given a task to design a syngas production plant and towards the end of the process we are going to use the pressure swing adsorptionvacuum swing adsorption to remove the carbon dioxide. Work on the curve for scale up.

Out the batch processing in two steps. Adsorption Processes Adsorption is the process of transferring material from a fluid phase to a solid phase. At the column exit there is a manual needle valve which is used to control system pressure during experiments.

Condenser distillation column extraction 5. Obtain the breakthrough curve. The appropriateness of the design technique was verified by comparing the estimated breakthrough data and column design parameters with conventional scale-up and kinetic approaches.

Our In-Line Adsorption Columns remove moisture oil and impurities from gases before analysis. Change the temperature until you get some separation in the direction you want. Packed Column Design Use a pilot test column filled with the carbon to be used in full scale application.

Selection and peer-review under responsibility of COE of Sustainalble Energy System Rajamangala University of Technology Thanyaburi RMUTT doi. The feed i s first contacted with a fresh batch of. Timer splits effluent into different streams 4.

The mixed gas stream is fed into the column. PROCESS DESIGN MANUAL For CARBON ADSORPTION for the ENVIRONMENTAL PROTECTION AGENCY Technology Transfer By SWINDELL-DRESSIER COMPANY A DIVISION OF PULLMAN INCORPORATED 441 SMITHFIELD ST. Modelling the adsorption process 1Di usion I di usion of the adsorbate in the bulk uid usually very fast.

32 Schematic of adsorption column L qA q flow rate u volumetric flux or Darcy velocity The continuity equation can now be expressed as follows. Energy Procedia 34 2013 83 â 90 1876-6102 Â 2013 The Authors. The time to reach the breakthrough point and shape of the breakthrough curve are very important characteristics for determining the operation and the dynamic responses of an adsorption column.

Published by Elsevier BV. Ozone-treated GAC 2088 mgg chitosan-coated GAC 1667 mgg HNO 3-treated GAC 1109. The performance of a fixed bed column can be described through the concept of breakthrough curve analysis.

CONTINUED Operating solvent flow rate FloodingDiameter collection Pressure drop Height of packing 5. The volume of liquid in a carbon column is simply the total volume of the column times the void fraction. The aim of this book is to provide all those involved in designing and running adsorption processes with a straightforward guide to the essentials of adsorption technology and design.

Up to 5 cash back A widely used method for adsorption of solutes from liquid or gases employs a fixed bed of granular particles. Each stream enters a separator eg. The housings come complete ready to install with the adsorbent of your choice included.

Design by Mass-Transfer-Zone Concept Chemical Engineering 1973. Apply a filtration rate and contact time EBCT which will be the same for full scale application to obtain similar mass transfer characteristics. Adsorption is a complex process and this makes the correct design and implementation of its operation all the more critical.

The fluid to be treated is usually passed down through the packed bed at a constant flow rate. The design of Cruz et. Ii φ cc t u c x si 0 The independent variables can be made dimensionless.

SERIES COLUMNSAn adsorption process in which the effluent from a first column becomes the influent for a second column the effluent from the second column becomes the influent for a third column and so on. PITTSBURGH PENNSYLVANIA 15222 Program 17020 GNR Contract 14-12-928 October 1971. In an adsorption process the solid is called the adsorbent and the solute is.

This is the most common type of adsorption column for wastewater treatment These columns must be provided with a system for the removal of spent carbon and the addition of fresh or regenerated carbon Because or their construction and operation downflow fixed-bed adsorbers also acts as depth filters for particles that can be. IJohnston Designing Fixed-Bed Adsorption Columns Chemical Engineering p 87-92 1972 ILukchis Adsorption Systems. Gabelman Process Solutions LLC Adsorption Basics.

101016jegypro201306736 10th Eco-Energy and Materials Science and Engineering. They are a simple cost effective solution for the adsorption of various chemicals within a gaseous stream. We will analyze the transport process involved in adsorption by progression in complexity from batch adsorption one-dimensional equilibrium adsorption on a column and one-dimensional non-equilibrium adsorption.

Dilute and immiscible gas-liquid phases L and V streams are constant from stage to stage Concentrated or miscible L and V streams can increase or decrease from stage to stage How will this affect the number of theoretical stages. Fundamentals of adsorption including equilibrium and mass-transfer considerations the mass-transfer zone concept breakthrough regeneration and column sizing. Feed mixture and recycle is pulse-injected into column 3.

Up to 10 cash back Removal of acetaminophen from synthetic wastewater in a fixed-bed column adsorption using low-cost coconut shell waste pretreated with NaOH HNO 3 ozone andor chitosan was performed and results of maximum adsorption capacity were. Using similitude rules on key design parameters a pilot-scale adsorption column was designed and break-through curves were generated using the validated HSDM.

Processes Free Full Text Continuous Fixed Bed Co2 Adsorption Breakthrough Column Efficiency Mass Transfer Zone Html

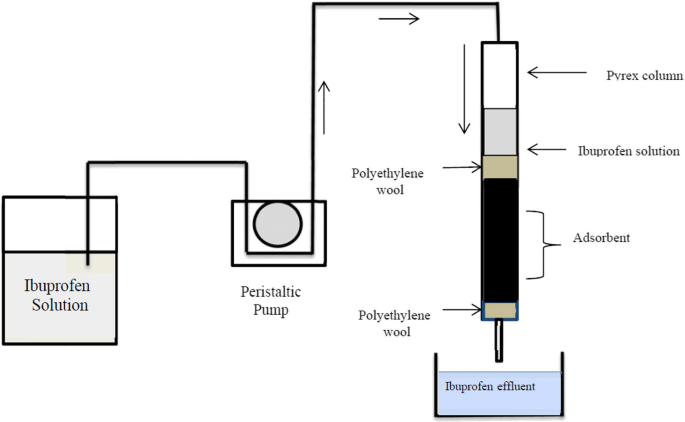

Fixed Bed Adsorption Column Studies And Models For Removal Of Ibuprofen From Aqueous Solution By Strong Adsorbent Nano Clay Composite Springerlink

Investigation Of Fixed Bed Adsorption Column Operation Parameters Using A Chitosan Material For Treatment Of Arsenate Contaminated Water Sciencedirect

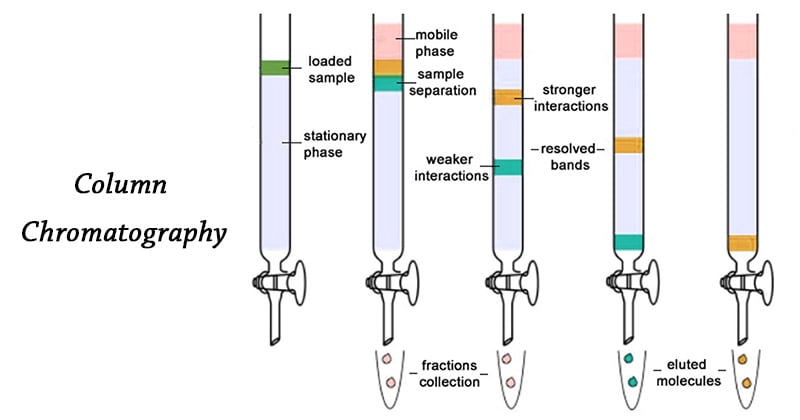

Column Chromatography Teaching Chemistry Chemistry Chemistry Posters

Adsorption Columns Equipment How Do They Work Lec127 Youtube

Schematic Representation Of Laboratory Scale Packed Bed Adsorption Download Scientific Diagram

Converting Coconut Shell To Activated Carbon Is An Interesting Process Coconut Coconut Shell Activated Carbon

Comments

Post a Comment